The main purpose:

The concept of ESG sustainable development continues to ferment around the world. Looking at the world, industry indicators including Apple and Nike have made major moves to propose ESG development goals. Important issues such as green energy, carbon reduction, and environmental protection have become necessary conditions for European and American brands to select suppliers. Through the Eco-GloMo green energy, carbon reduction, and environmental protection double E (EPS+ESG) equation, the manufacturing process of dipped NBR gloves is provided to meet the needs of green energy, carbon reduction, and environmental protection. Listed as CSR and tracked

characteristic:

1. Does not contain Silicone, suitable for the production line of gloves used in the semiconductor industry.

2. It does not contain protein, and will not cause allergies to the finished glove to the human body.

3. Gloves with low pinholes have good elongation, softness, needle resistance, tensile strength and durability.

4. Gloves have excellent stability and film-forming properties.

5. The energy-saving efficiency of the motor of the glove production line is as high as 30% (max), and the energy saving and carbon emission are as high as 20% (max).

6. Provide zero landfill waste and recyclable products that meet the requirements of green products.

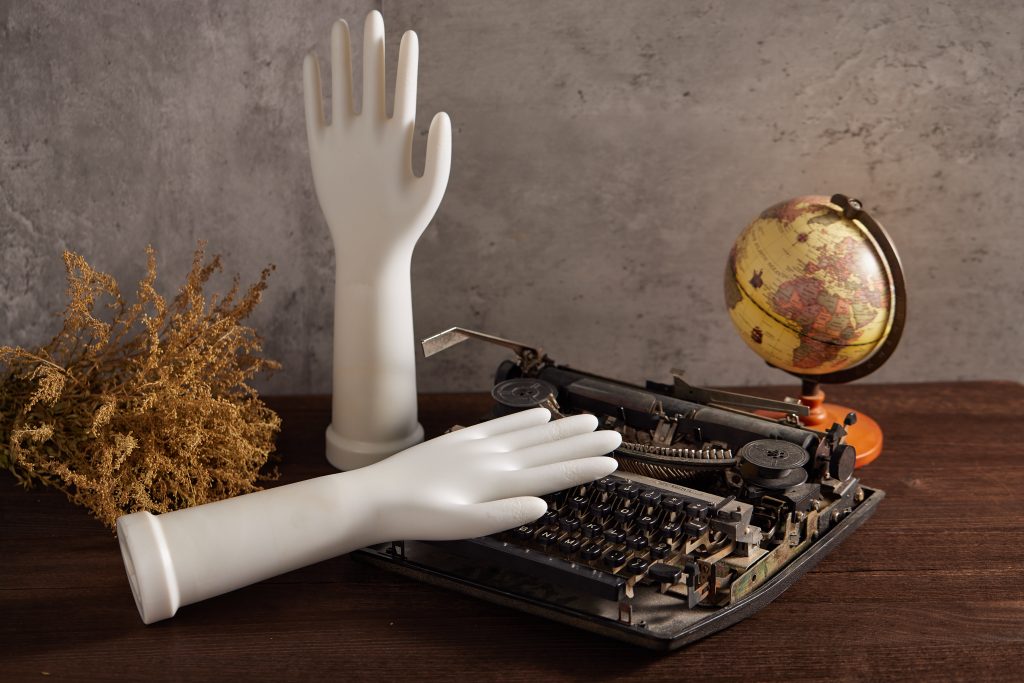

Nitrilepattern, inspection, medical gloves, household gloves, industrial gloves,PUglove mold–Multiple models

|

model(size) |

S,M,L |

|

high(Height) |

370,400,420mm |

|

Pockmarked(Texture) |

According to customer requirements |

|

pockmarked location(Texture Area) |

Finger numbness, fingertip numbness, general numbness, palm numbness |

|

physical index Physical and Chemical Indicators |

|

|

water absorption |

1.5% |

|

heat resistance |

180°C |

|

Bulk density |

1.2 g/cm3 |

|

Alkali resistance |

>99% |

|

porosity |

0% |

|

Impact strength |

>400kgf |

user's Guide:

1. Please check the Eco-GloMo Hand Stencil for breakage or obvious cracks before use. Do not use if damaged.

2. Please wear gloves when using to avoid direct contact with Eco-GloMo.

3. Before use, it is recommended to soak the Eco-GloMo hand model in water. It is forbidden to use concentrated nitric acid 68% for soaking and cleaning, so as to enhance the anti-sticking property of the Eco-GloMo hand model.

4. Place the plastic stretch film or other packaging material on the Eco-GloMo hand mold and close the mold tightly.

5. Eco-GloMo prohibits the use of open flames, oil temperature and infrared heat sources to heat the oven, and the oven temperature does not exceed 180°C.

6. Eco-GloMo prohibits the use of concentrated nitric acid 68%. It is recommended to use nitric acid solution (below 1.5% is the most suitable) to clean Eco-GloMo hand molds or use it after scrubbing with clean water.

7. Eco-GloMo uses sodium hydroxide. It is recommended to use sodium hydroxide solution or clean water to clean Eco-GloMo hand molds before use.

8. In order to maintain the service life of Eco-GloMo, please wash and dry it after use. Eco-GloMo has a service life of at least 3 years under the conditions recommended by our company, and the warranty is one year.

The above are the basic instructions for use of Eco-GloMo hand molds, however, different Eco-GloMo hand molds have different uses and characteristics, please read the detailed instructions for use before use in order to use them properly